Materials

We meticulously select premium raw materials to craft products that unite reliability, durability, and aesthetic appeal. In this section, discover comprehensive details about our materials—their properties, advantages, and why they form the foundation of superior product quality.

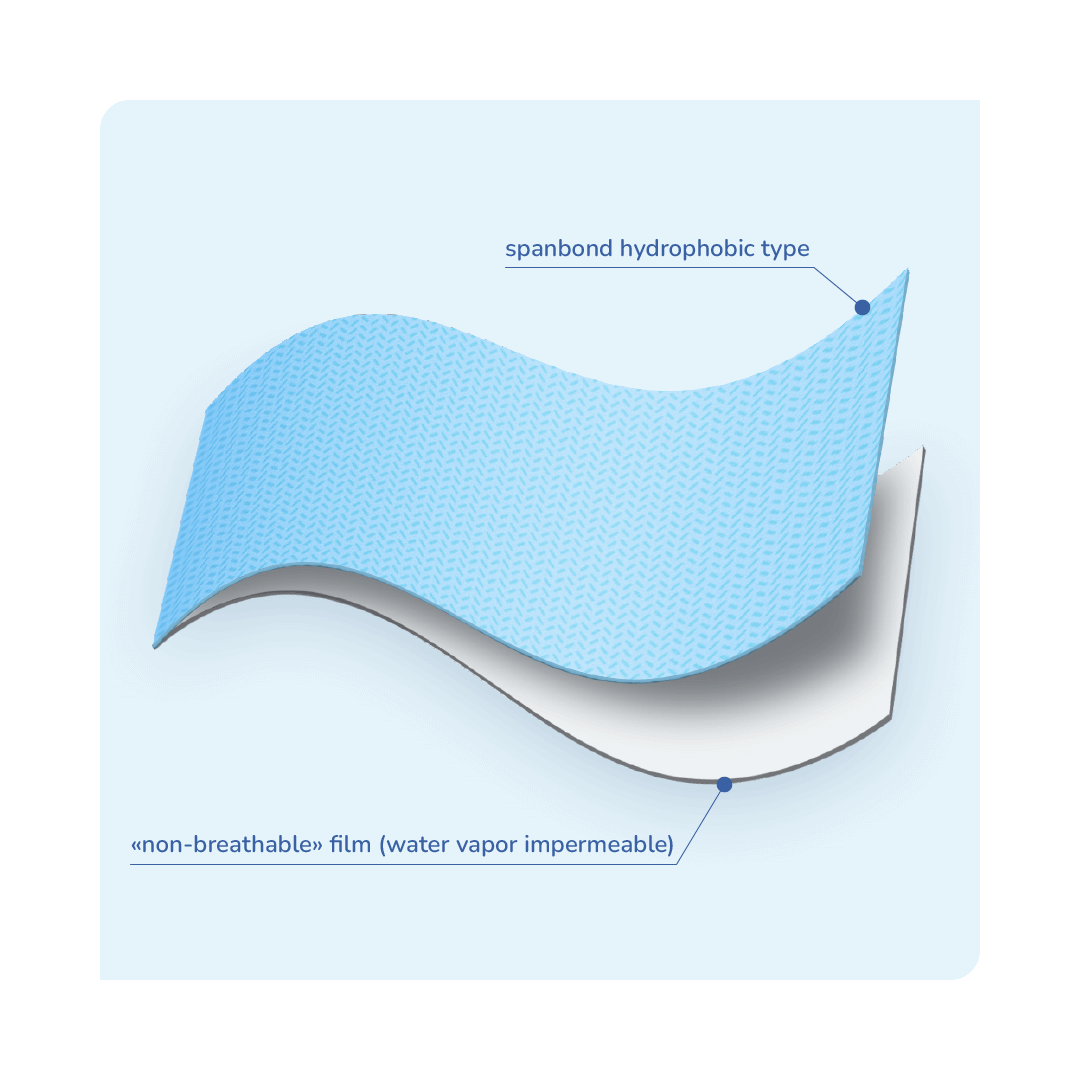

Base (laminated spunbond)

Laminated material made of hydrophobic spunbond and vapor-impermeable film

- Provides a complete barrier to liquids and high bacterial and viral protection, without air and vapor permeability

- Designed for surgical gowns and areas with intensive contact with liquids

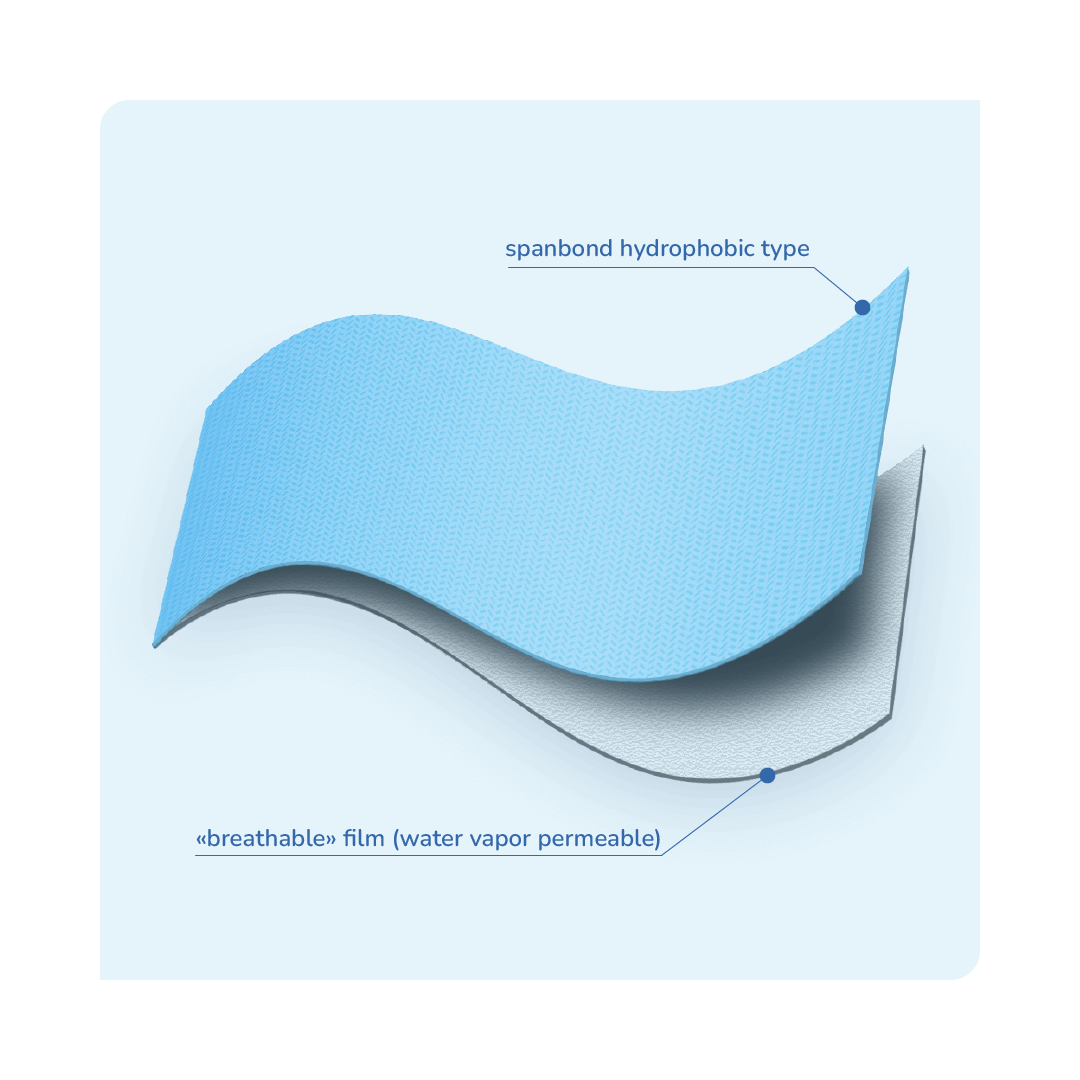

Base Aero (laminated spunbond)

A combination of hydrophobic spunbond with a breathable film

- Provides complete protection against liquids while maintaining moderate air and vapor permeability

- Ideal for long procedures where a balance of protection and comfort is important

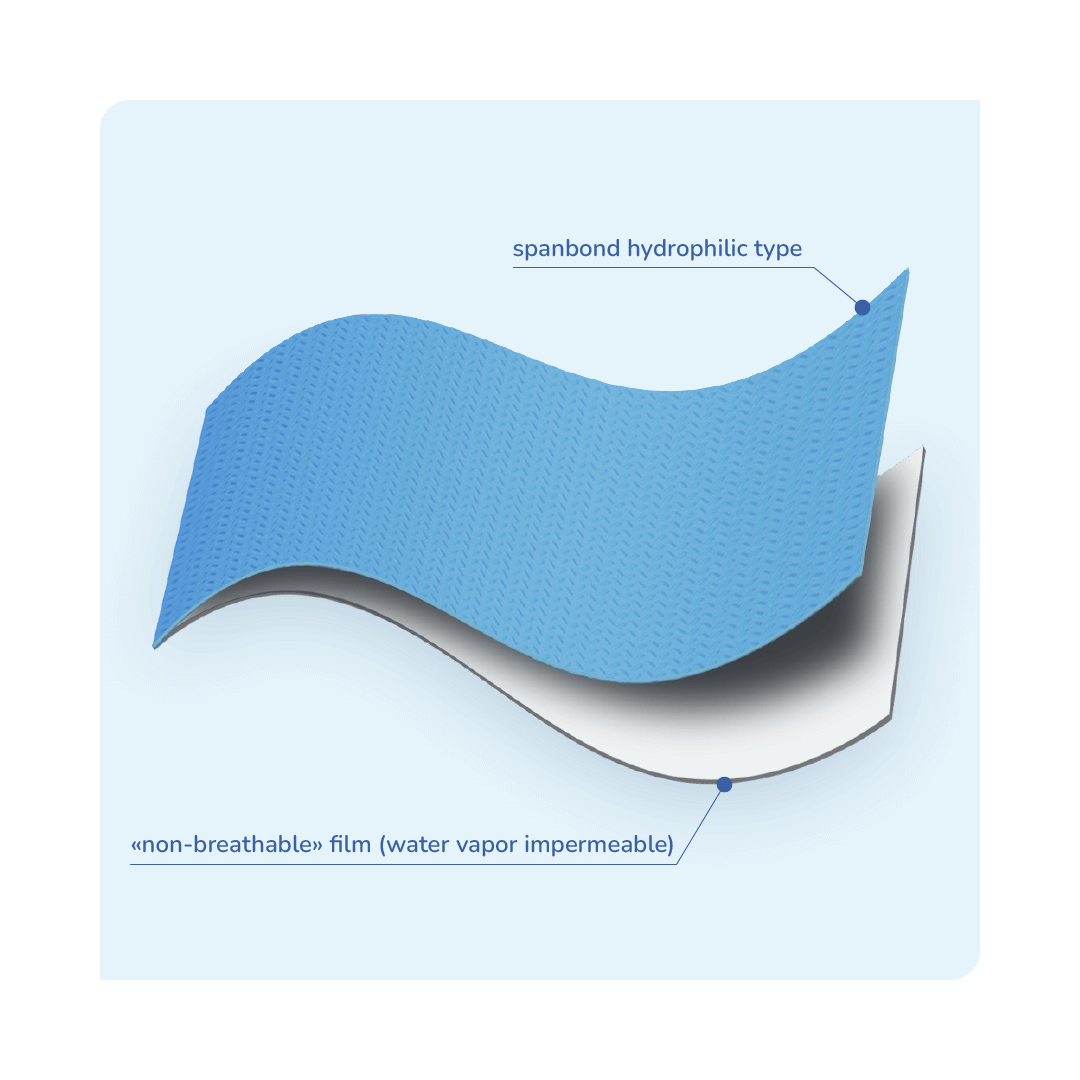

Light (laminated spunbond)

A material with a hydrophilic outer layer and a vapor-impermeable film

- It completely blocks the penetration of liquids, actively absorbing them from the surface

- It is used in gowns and operating room covers

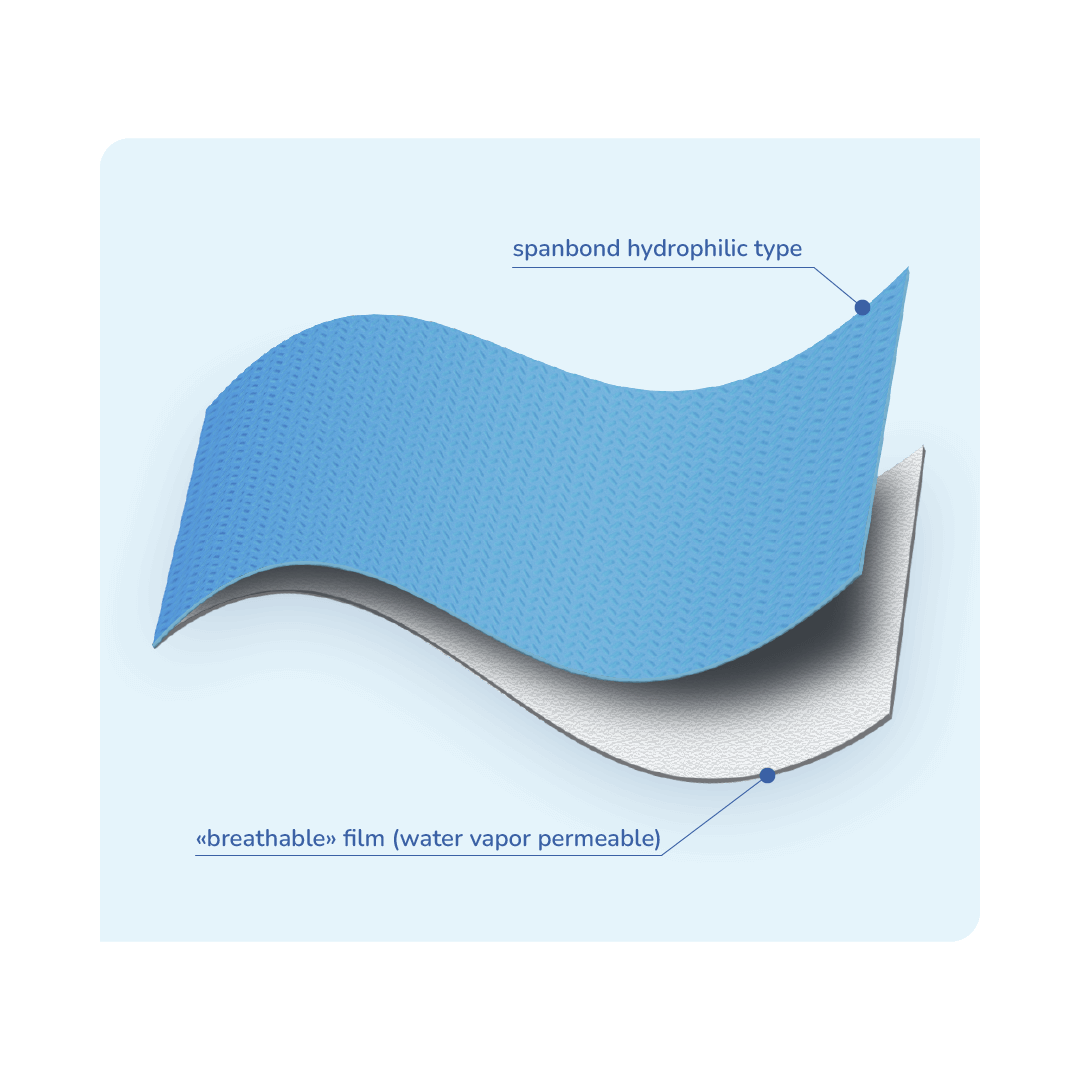

Light Aero (laminated spunbond)

Hydrophilic spunbond combined with a vapor-permeable film

- Provides zero permeability to liquids, high barrier properties, and increased comfort thanks to good vapor permeability

- Designed for comfortable surgical gowns

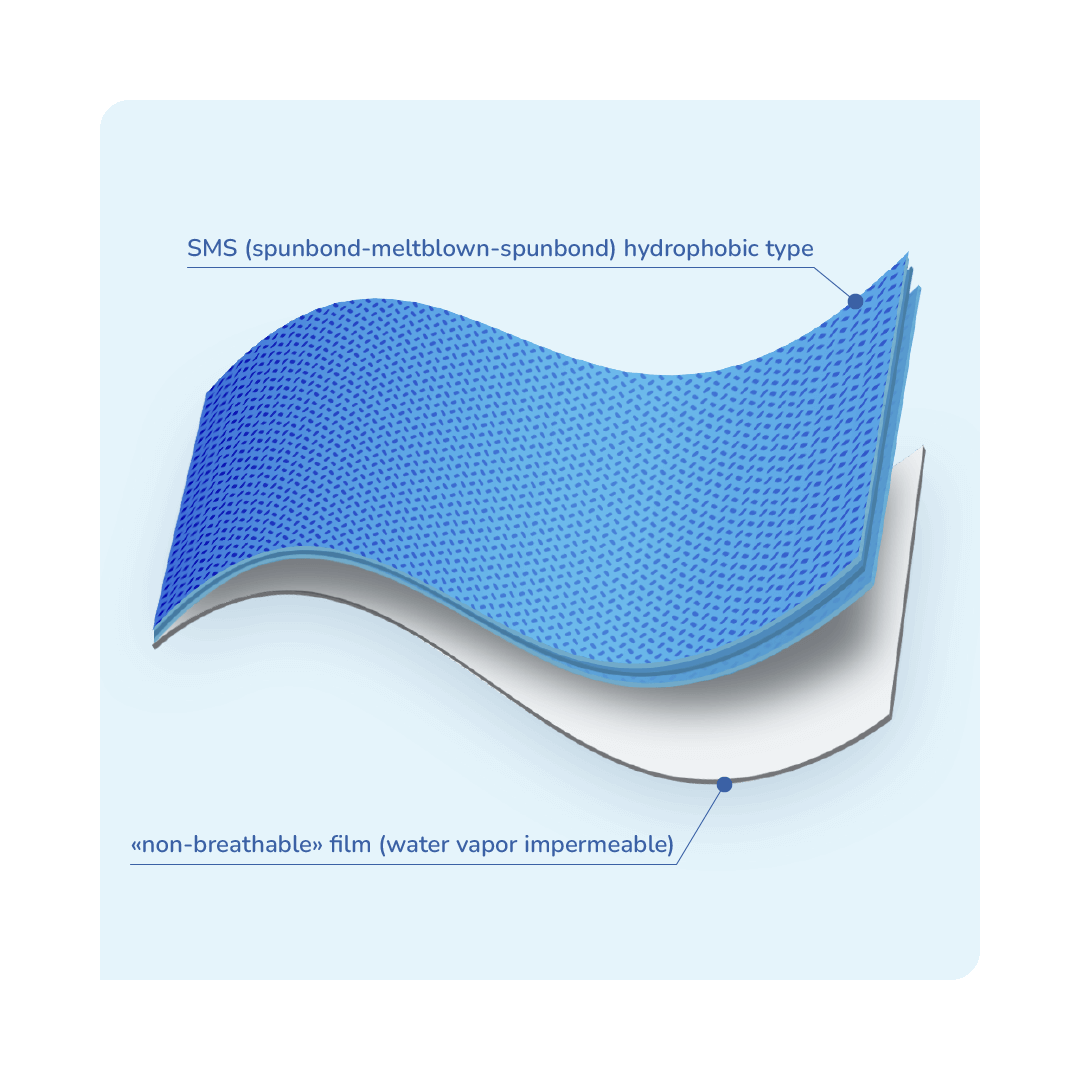

Standard (laminated SMS)

Laminated SMS with a vapor-impermeable film

- Zero permeability to liquids and very high barrier properties due to the SMS structure

- Used in surgical kits and protective gowns.

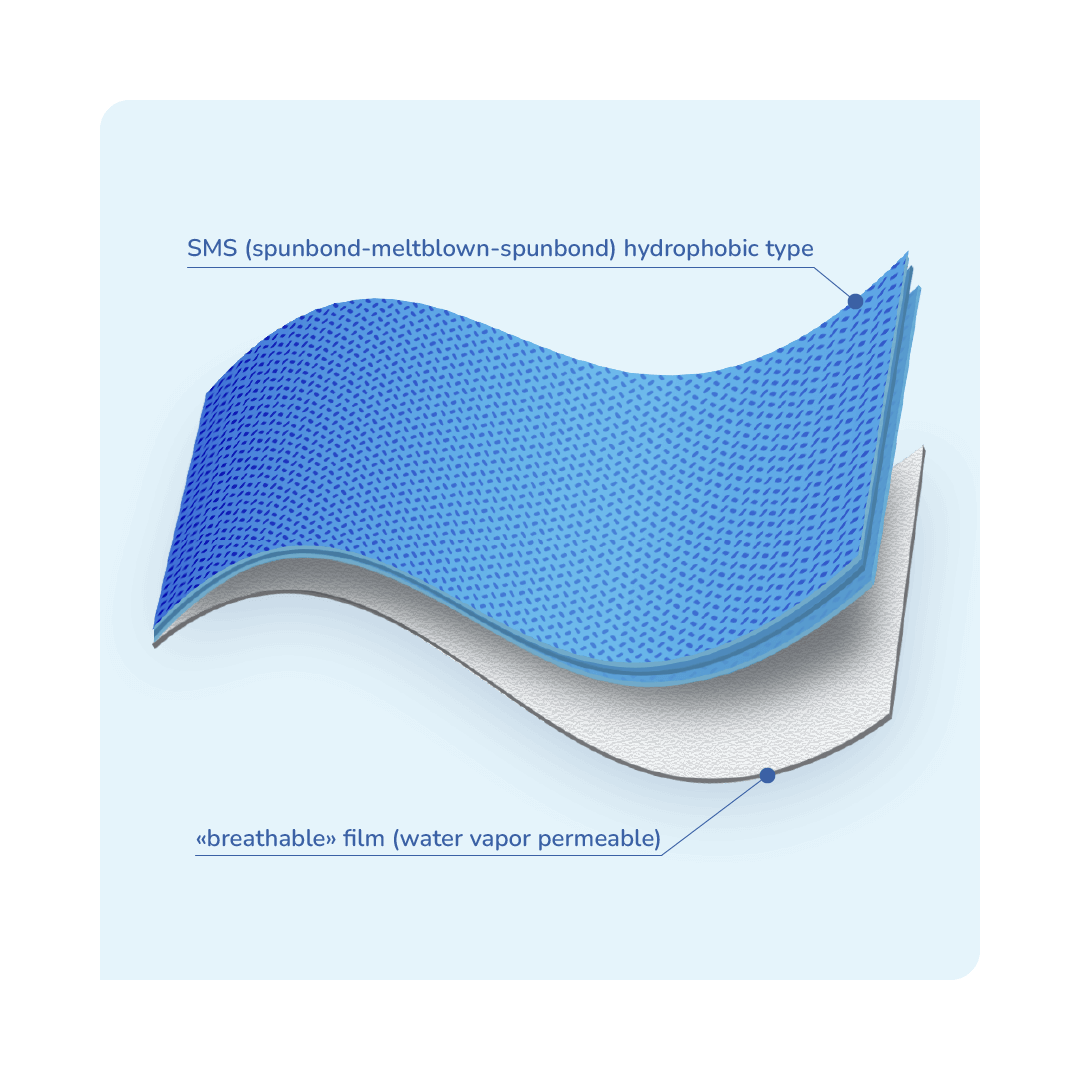

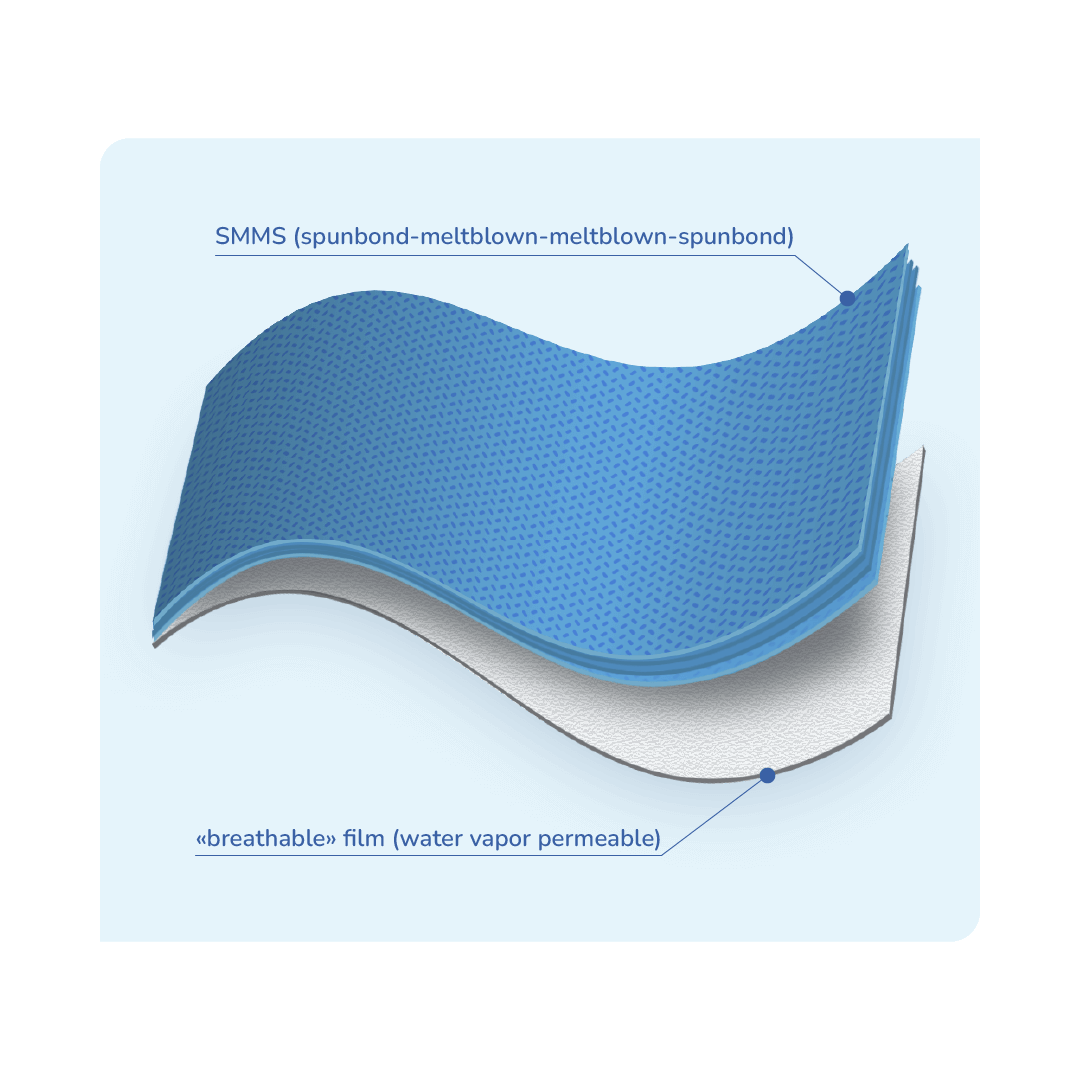

Standard AERO (laminated SMS)

SMS combined with a breathable film

- Provides a high level of barrier protection against liquids with medium air permeability and high vapor permeability

- Designed for premium gowns and covers for long operations

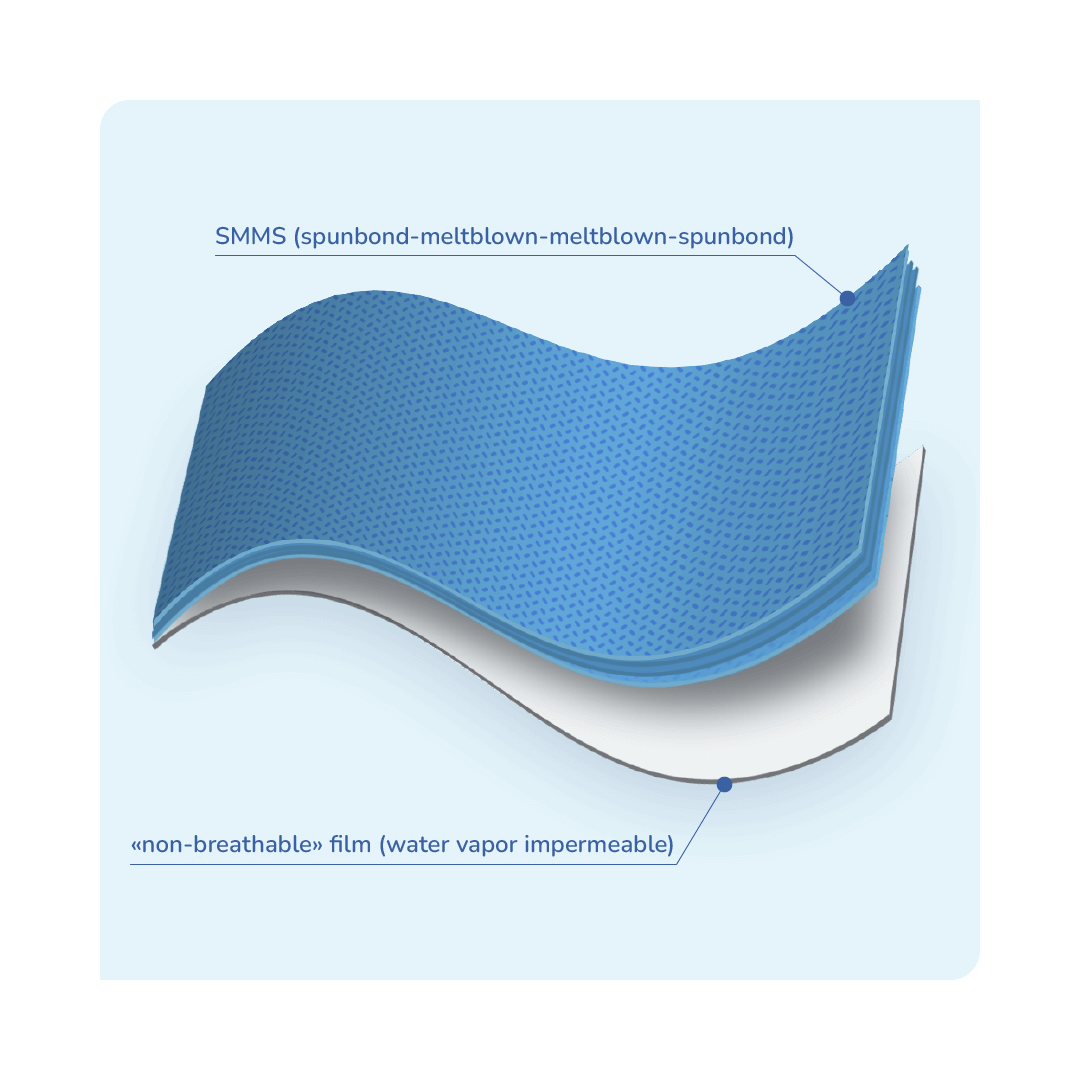

Standard “+” (laminated SMMS)

Laminated SMMS with a vapor-proof film

- Provides maximum barrier protection and complete impermeability to liquids

- Recommended for areas with large amounts of liquids and prolonged operations

Standard “+” Aero (laminated SMMS)

SMMS combined with a vapor-permeable film

- Combines maximum barrier properties with increased comfort during prolonged use

- Used in premium gowns and operating room coverings

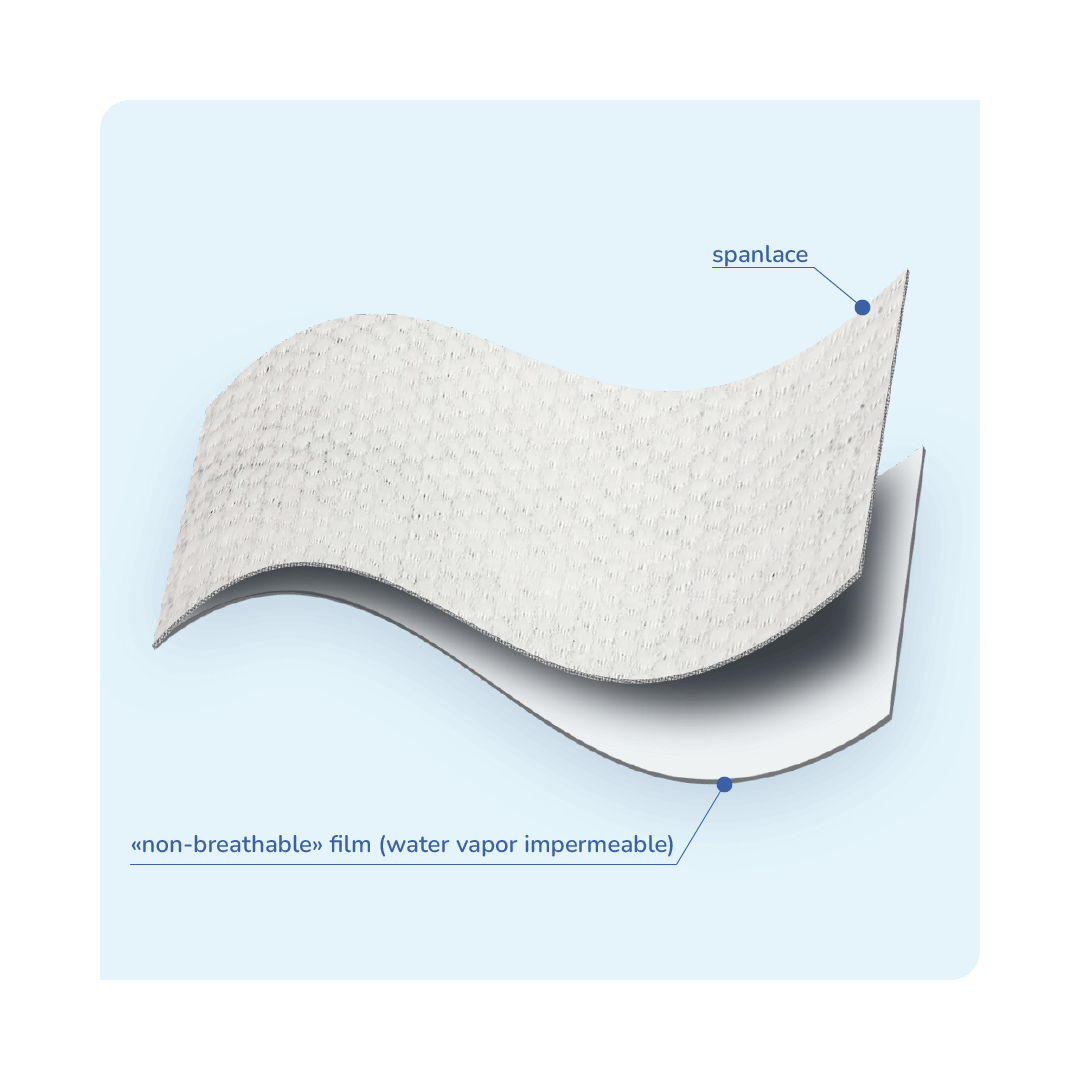

Soft (laminated spunlace)

Laminated spunlace with a vapor-proof film

- Provides zero permeability to liquids and a high level of protection while maintaining softness and pleasant tactile properties

- Used for protective elements in gowns and coverings during long operations

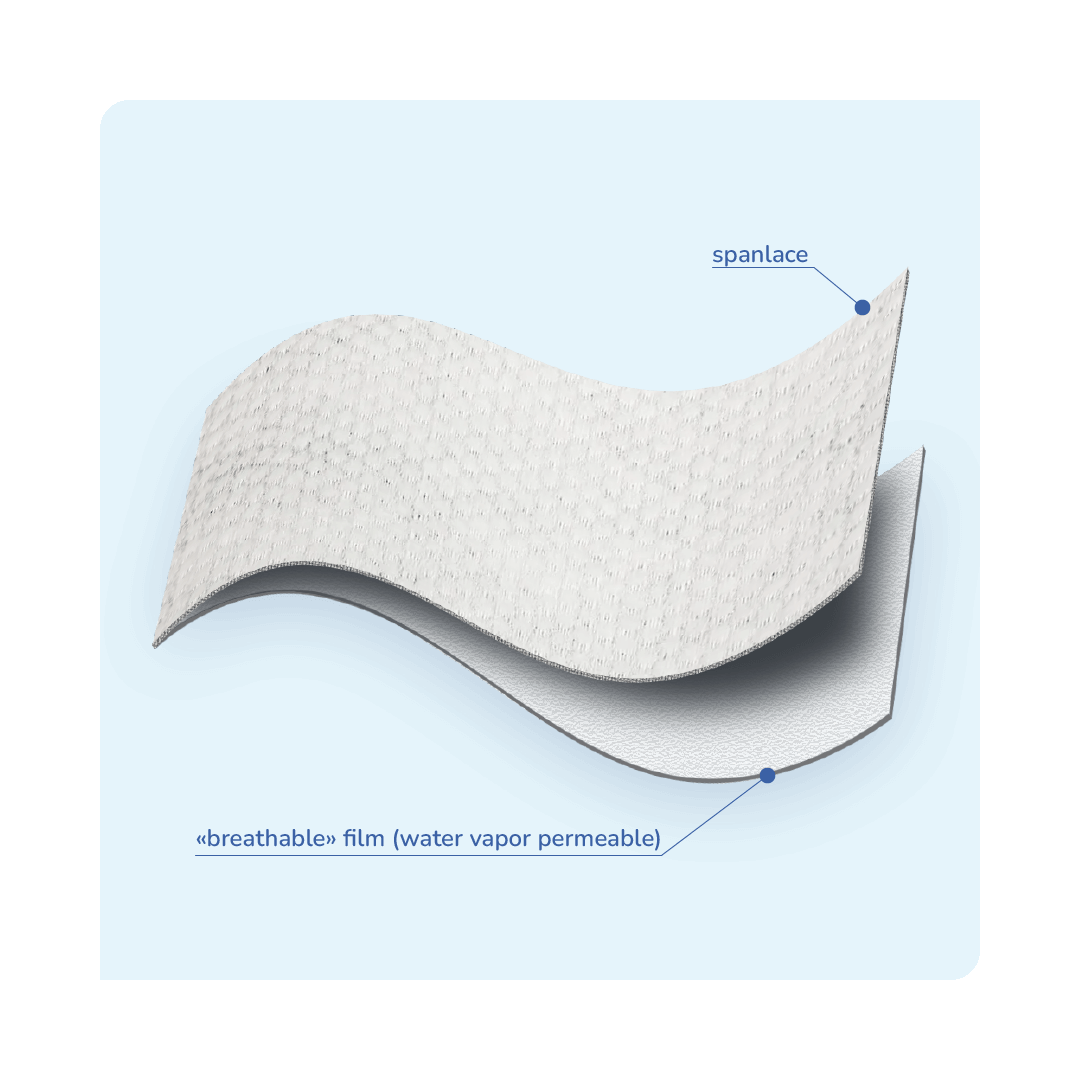

Soft Aero (laminated spunlace)

Spunlace combined with a breathable film

- Provides a complete barrier to liquids, high vapor permeability, and maximum comfort for staff

- Designed for premium surgical kits and long operations